I. Basic Information

Since its founding in 2003, SKSHU Paint Co., Ltd. (“3TREES”) has been committed to building healthy homes by providing an integrated 6-in-1 one-stop system of green construction materials and services, encompassing interior and exterior wall coatings, waterproofing products, insulation materials, auxiliary materials, floor coatings and construction. In 2016, 3TREES was listed on the A-share main board of the Shanghai Stock Exchange, becoming the first civilian paint company to get listed in China. Headquartered in Putian, Fujian Province, 3TREES has set up seven production bases in Tianjin, Chengdu, Nanyang, Chuzhou, Baoding and other places. More than 5,000 employees from all over the country work happily in this garden-like company. Characterized by its “Imitation of Nature” culture and with the beautiful eco-industrial park, the company has won the title of China’s Green Plant and was praised by leaders at all levels in China.

SKSHU Paint Co., Ltd. (Putian Plant) has annual designed production capacities are as follows: 10,300t/a alkyd resin, 1,500t/a acrylic resin 1,500t/a UV curable resin, 4,800t/a curing agent, 100,000t/a emulsion paint, 110,000t/a natural stone texture paint, 7,000t/a granite paint, 30,000t/a auxiliary materials, 30,000t/a wood paint and 25,000t/a adhesive, all of which has been completed and passed completion acceptance inspection. 3TREES’s Putian Plant covers an area of 174,186m2 or approximately 261mu.

Located in the Licheng Economic Development Zone of Putian City (within the factory area of SKSHU Paint Co., Ltd. (Putian Plant)), Fujian Sanjiang Packaging Co., Ltd. mainly produces tinplate packaging barrels. Its annual designed production capacities are as follows: 2.975 million 18L color barrels, 1 million 18L barrels, 1.134 million 5L round barrels, 1.134 million 4L round barrels, 4.5 million 2L barrels, 1.1592 million 1L square barrels, 2.4192 million 2L square barrels, and 2.4192 million 4L square barrels. The project covers an area of 14,150m2 or approximately 21.2mu.

Established in 2013, Tianjin SKSHU Paint Co., Ltd. (Tianjin Plant) currently rents industrial factory buildings in Shuangkou Town Industrial Zone, Beichen District, Tianjin. It has purchased corresponding production equipment and waste gas and sewage treatment facilities to produce emulsion paint, texture paint and granite paint. Its annual designed production capacities are as follows: emulsion paint: 20,000t/a; texture and granite paint: 30,000t/a; and putty powder: 10,000t/a. The project passed environmental acceptance inspection on October 25, 2014.

Established in 2015, Henan SKSHU Paint Co., Ltd. (Henan Plant) is located in the Nanzhao County Industrial Agglomeration Zone in Nanyang City, Henan Province. It currently rents industrial factory buildings, covering a total area of about 19,677m2. The plant mainly produces waterborne coatings and supporting materials. Its annual designed production capacities are as follows: 200,000 tons of waterborne coatings, and 3 million packaging barrels. The first-phase 100,000t/a waterborne coating project passed environmental acceptance inspection on August 29, 2017. The newly expanded phase II water-borne coating project with an annual output of 100,000 tons passed environmental acceptance inspection on October 29, 2018, and the 3 million packaging barrels project passed the environmental protection completion acceptance inspection on December 28, 2018.

Sichuan SKSHU Paint Co., Ltd. (Sichuan Plant), established in 2015, is located in Qionglai Industrial Park of Tianfu New Area in Chengdu, Sichuan Province. Covering a land area of 221,321.33m2 or approximately 331.982mu. it mainly produces coatings and auxiliary materials. Its current annual production capacities are as follows: 5,000 tons of curing agent, 30,000 tons of wood paint, 15,000 tons of water-based adhesives, 150, 000 tons of natural stone texture paint, 180,000 tons of emulsion paint, 90,000 tons of putty powder, 12 million packaging barrels, 10,000 tons of polyurethane waterproof paint, 800 tons of diatom mud, 3 million square meters of integrated thermal insulation boards, 20 million square meters of modified asphalt waterproof sheets with padding, 20 million square meters of modified asphalt waterproof sheets without padding, 7 million square meters of polymer waterproof sheets, and 5 million square meters of non-asphalt self-adhesive film waterproof sheets. Currently, all the production capacities have been completed and are undergoing acceptance inspection.

Anhui SKSHU Paint Co., Ltd. (Anhui Plant) was established in 2017. The planned plant within the red lines covers a land area of 250,685.5m2, with a total construction area of 169,000 m2. The plant mainly engages in the production and sales of coating, waterproof materials, new insulation materials, adhesives and other chemical products, as well as packaging materials. The company has invested in a coating production and supporting construction project in the Mingguang City Chemical Industry Agglomeration Zone, Anhui Province. Its current annual production capacities are as follows: 300,000 tons of emulsion paint, 200,000 tons of natural stone texture paint, 15,000 tons of waterproof paint, 20,000 tons of granite paint, 300,000 tons of putty powder, 40,000 tons of tile sealer, 5,000 tons of interfacial agent, 30 million cans, 10 million square meters of modified asphalt waterproof sheets with padding, 10 million square meters of modified asphalt waterproof sheets without padding, 1,800 million eco-boards, 30,000 tons of water-based adhesives and 60,000 tons of polyurethane waterproof paint. Currently, all the production capacities have been completed and are undergoing acceptance inspection.

II. Construction and Operation of Pollution Control Facilities

1. SKSHU Paint Co., Ltd. (Putian Plant)

In strict accordance with the "Three Concurrents" requirements for construction projects, SKSHU Paint Co. Ltd. has improved its various environmental protection facilities to ensure stable and compliant emission. All its workshops are equipped with dedusting and degassing facilities. In the meantime, the company has also built a sewage treatment station, standardized solid waste storage site construction, and taken protective measures against wind, rain, leakage and loss. Its main environmental protection facilities include:

Waste gases generated in the company’s Wood Paint Workshops A and B, Adhesive Workshop and Resin Workshop are treated by pulse deposition dust removal + zeolite molecular sieve adsorption concentration runner + RTO regenerative combustion device, which can meet the requirements of Table 2 of Integrated Emission Standard of Air Pollutants (GB 16297-1996) and Table 4 of Emission Standard of Pollutants for Synthetic Resin Industry (gb31572-2015). Waste gases generated in emulsion, texture, granite and auxiliary material workshops are emitted according to the standard after collection by pulse-type precipitators. The precipitators mainly remove dust from the waste gases, reduce the emission of harmful substances such as particulate matter and meet the Grade II Standard in Table 2 of Integrated Emission Standard of Air Pollutants (GB 16297-1996).

Domestic sewage in the plant area is directly discharged into the municipal pipe network after passing through a septic tank. It meets the Grade II Discharge Standard in Table 4 of Integrated Wastewater Discharge Standard (GB8978-1996) and the Grade B Standard of Wastewater Quality Standard for Discharge into Urban Sewers (GB/T31962-2015). Production wastewater is discharged into the comprehensive sewage treatment station in the plant area after being treated by the pretreatment station. The sewage stations adopt a combination of physicochemical and biochemical methods to ensure stable treatment effect and high pollutant removal rate. Production wastewater discharge meets the Grade III Standard in Table 4 of Integrated Wastewater Discharge Standard (GB8978-1996). After entering the municipal sewage pipe network, production wastewater is brought to the Minzhong Sewage Treatment Plant for further treatment. Currently, the company has a resin organic wastewater treatment system to treat high concentration organic wastewater in accordance with the Discharge Standard of Pollutants for Synthetic Resin Industry (GB31572-2015). However, following a product structure adjustment, the company has stopped resin production, and the system was put out of service in July 2019.

To eliminate the impact of the noise inside the plant on outside residents, various measures have been taken in the workshops/factory buildings that are prone to cause big noise. For example, low-noise facilities and sound insulation doors are adopted for air compressor equipment to reduce noise. Thanks to these measures, noise at the boundary of the plant meets the Type III limit values of Emission Standard for Industrial Enterprises Noise at Boundary (GB 12348-2008).

Through the above-mentioned environmental protection measures, the treated sewage, waste gases and noise at SKSHU Paint Co., Ltd. have reached the emission standards specified in the EIA written reply document. All environmental protection facilities can operate stably, and the synchronous operation rate of the facilities meets the requirement.

2. Fujian Sanjiang Packaging Co., Ltd.

In strict accordance with the "Three Concurrents" requirements for construction projects, Sanjiang Packaging has improved its various environmental protection facilities to ensure stable and compliant emission. Its workshops are equipped with 3 gas collection systems, and gas emission meets the Grade II Standard in Table 2 of Integrated Emission Standard of Air Pollutants (GB16297-1996).

Through the above-mentioned environmental protection measures, the treated waste gases at Sanjiang Packaging have reached the emission standards specified in the EIA written reply document. All environmental protection facilities can operate stably, and the synchronous operation rate of the facilities meets the requirement.

3. Tianjin SKSHU Paint Co., Ltd. (Tianjin Plant)

In strict accordance with the "Three Concurrents" requirements for construction projects, Tianjin SKSHU has improved its various environmental protection facilities to ensure stable and compliant emission. Waste gases generated in the production workshops are treated by submerged filter cartridge dust removal device and photocatalyst waste gas purifier, which meets the Grade II Standard in Table 2 of Integrated Emission Standard of Air Pollutants (GB16297-1996).

Production wastewater is treated by the "physicochemical + biochemical" treatment process through the sewage treatment station in the plant area, and is discharged after reaching the Grade III standard of Integrated Wastewater Discharge Standard (D12/356-2008). After entering the municipal sewage pipe network of the industry park, the production sewage is finally discharged into the Shuangqing Sewage Treatment Plant for centralized treatment.

Through the above-mentioned environmental protection measures, the treated sewage and waste gases at Tianjin SKSHU have reached the emission standards specified in the EIA written reply document. All environmental protection facilities can operate stably, and the synchronous operation rate of the facilities meets the requirement.

4. Henan SKSHU Paint Co., Ltd. (Henan Plant)

In strict accordance with the "Three Concurrrents" requirements for construction project, Henan SKSHU has built various environmental protection facilities to ensure stable and compliant emission. Waste gases generated in the production workshops are discharged after being treated by bag filter + photocatalysis + activated carbon adsorption, and meet the Grade II standard in Table 2 of Integrated Emission Standard of Air Pollutants (GB 16297-1996).

Production wastewater is treated by the "physicochemical + biochemical" treatment process through the sewage treatment station in the plant area, and discharged into the Nanzhao County Sewage Treatment Plant for centralized treatment. It meets the discharge standard of the inlet sewage pipe network of the Nanzhao Sewage Treatment Station.

Through the above-mentioned environmental protection measures, the treated sewage and waste gases at Henan SKSHU have reached the emission standards specified in the EIA written reply document. All environmental protection facilities can operate stably, and the synchronous operation rate of the facilities meets the requirement.

5. Sichuan SKSHU Paint Co., Ltd. (Sichuan Plant)

In strict accordance with the "Three Concurrents" requirements for construction projects and its EIA report, Sichuan SKSHU has built various environmental protection facilities. Dust-containing gases generated in the water-based workshops are discharged up to the standard after being treated by submerged filter cartridge dust collectors. Dust-containing organic waste gases generated in the oil-based workshops are pretreated by submerged filter cartridge dust collectors, and then pass through molecular sieve adsorption concentration runner + RTO thermal storage combustion device. The waste gas treatment facilities meet the requirements of Integrated Emission Standard of Air Pollutants (GB16297-1996), Emission Standard of Sichuan Province for Atmospheric Volatile Organic Compounds from Fixed Pollution Sources (DB51/2377-2017) and Emission Standard of Odor Pollutants (GB14554-93)

Production wastewater and domestic sewage in the plant area are treated by the sewage treatment station in the plant area. Production wastewater is firstly treated by "high efficiency air flotation + micro electrolysis", and then by "anaerobic biological filter + biological contact oxygen" along with the domestic sewage. After reaching the Grade III Standard in Table 4 of Integrated Wastewater Discharge Standard (GB8978-1996), production wastewater enters Qionglai City No.3 Wastewater Treatment Plant through the municipal sewage pipe network for treatment, before being discharged into the Xiajiang River.

Through the above-mentioned environmental protection measures, the treated sewage and waste gases at Sichuan SKSHU have reached the emission standards specified in the EIA written reply document. All environmental protection facilities can operate stably, and the synchronous operation rate of the facilities meets the requirement.

6. Anhui SKSHU Paint Co., Ltd. (Anhui Plant)

In strict accordance with the "Three Concurrents" requirements for construction projects and its EIA report, Anhui SKSHU has built various environmental protection facilities. Following pulse filter + UV photolysis + secondary activated carbon adsorption treatment, waste gases generated in the production of emulsion, granite, natural stone texture paints and sample boards at the comprehensive workshops can reach the Grade II Emission Standard of Integrated Emission Standard of Air Pollutants (GB 16297-1996), the emission limits of Table 1 of Emission Standard of Volatile Organic Compounds Part 6: Organic Chemical Industry and Table 1 of Emission Standard of Volatile Organic Compounds Part 7: Other Industries. Waste gases generated in the production of polyurethane waterproof coating, water-based adhesives and Phase II thermal insulation integrated boards are collected for pulse dust removal treatment, while VOCs are treated by "molecular sieve runner + RTO thermal storage combustion" to meet the requirements of Table 5 Special Emission Limits of Air Pollutants of Emission Standard for Pollutants in Synthetic Resin Industry (631572-2015), the special emission limit requirements of Emission Standard of Air Pollutants for Cement Industry (GB4915-2013), and the emission limits in Table 1 of Emission Standard for Volatile Organic Compounds Part 7: Other Industries. Waste gases generated in the production of asphalt waterproofing rolls are treated by oil spray absorption tower washing + double-layer electrostatic capture + filter filtration + UV photodegradation to meet the Time Period II standard limit requirements of Emission Standard Of Air Pollutants for Waterproofing Roll Industry (DB11/1055-2013). Waste gases generated from the sewage treatment station are treated by spray tower + photocatalytic oxidation device to meet the requirements of Emission Standard for Odor Pollutants (GB 14554-93).

Production wastewater is pretreated by the sewage treatment station in the plant area, and domestic sewage enters the sewage treatment station in the plant area for treatment by using "grid + primary sedimentation + flocculation sedimentation + micro electrolysis + biological anaerobic + biological contact oxidation + secondary sedimentation tank + mixed flocculation + aerated active filter tank" processes. Wastewater from the treatment of polyurethane waterproof coating and water-based adhesives is treated to meet Discharge Standard of Pollutants for Synthetic Resin Industry (GB31572-2015). Sewage discharged from the plant enters the Chengdong Sewage Treatment Plant through the municipal sewage pipe network.

Through the above-mentioned environmental protection measures, the treated sewage and waste gases at Anhui SKSHU have reached the emission standards specified in the EIA written reply document. All environmental protection facilities can operate stably, and the synchronous operation rate of the facilities meets the requirement.

III. Type, Quantity and Destination of Discharged Pollutants

1. Type, Quantity and Destination of Pollutants Discharged by SKSHU Paint Co., Ltd. (Putian Plant)

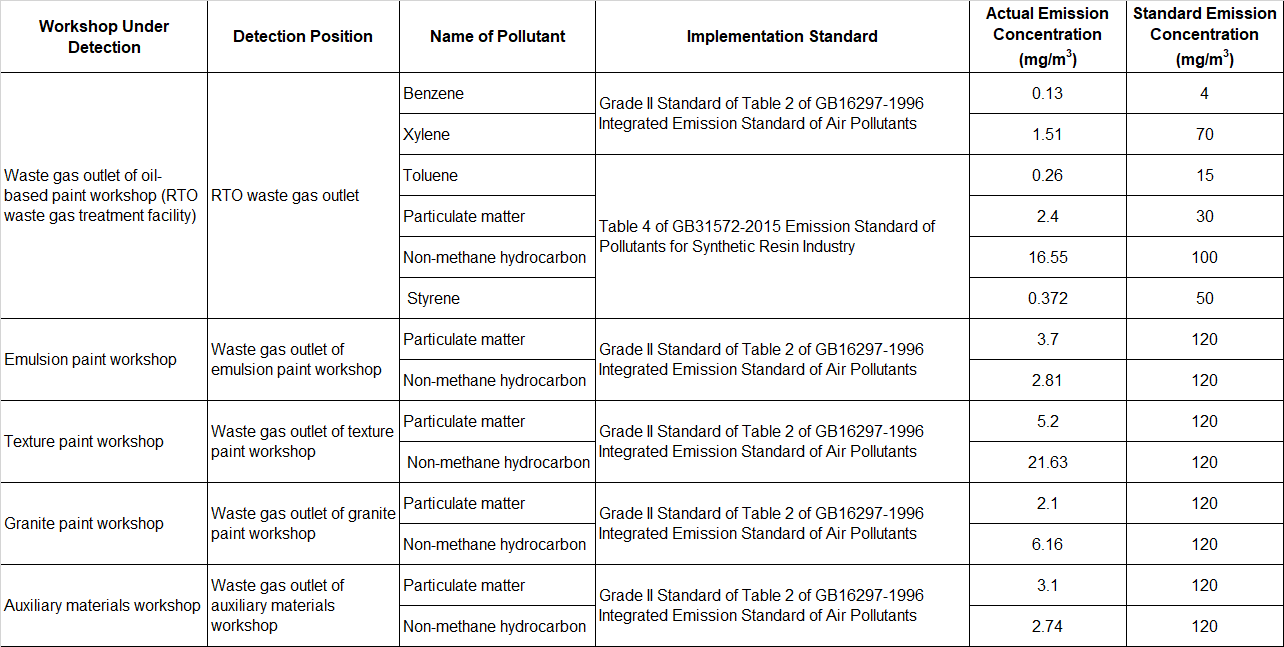

(1) The main pollutants of waste gas emissions include: non-methane hydrocarbon, benzene, toluene, xylene, particulate matter, etc.

Note: Data source - test report of Fujian Zhongkai Detection Technology Co., Ltd. on September 17, 2019 (No.: ZK191090225).

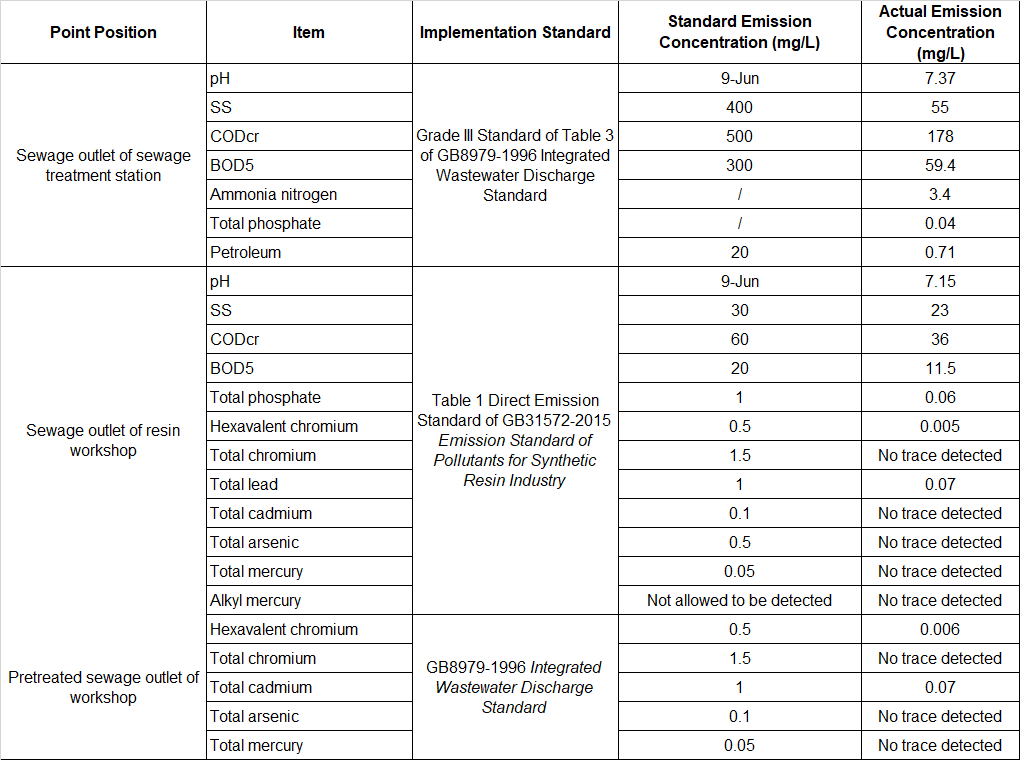

(2) After treated by the company's sewage treatment station, sewerage is discharged into the municipal sewage pipe network and then the Minzhong Sewage Treatment Plant for centralized treatment.

Note: Data source - the test reports of Fujian Zhongkai Detection Technology Co., Ltd. on July 19, 2019 (No.: ZK19070212) and September 17, 2019 (No.: ZK191090225).

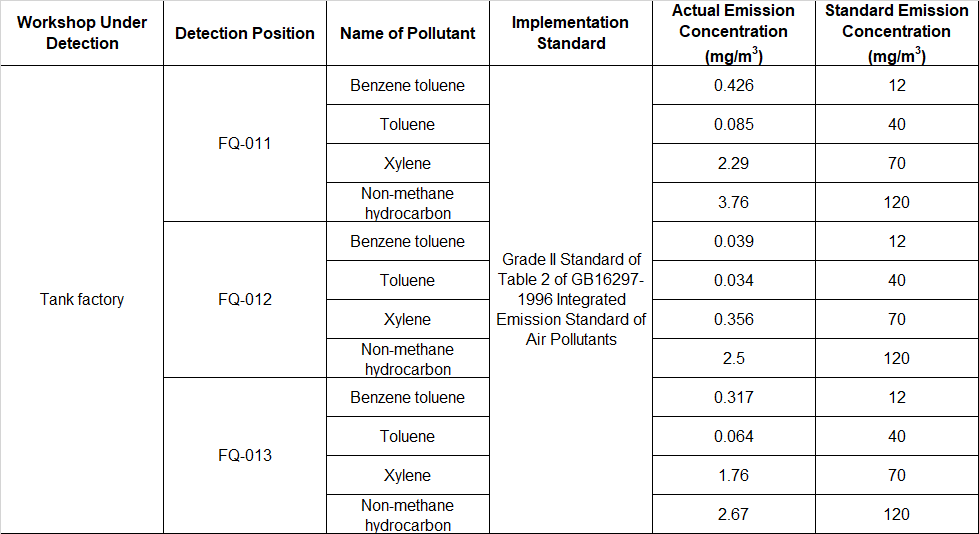

2. Types, Quantity and Destination of Pollutants Discharged by Fujian Sanjiang Packaging Co., Ltd,

The main pollutants of waste gas emissions include: non methane hydrocarbon, benzene, toluene and xylene.

Note: Data source - test reports of Fujian Zhongkai Detection Technology Co., Ltd. on August 17, 2019 (No.: ZK19080215) and September 18, 2019 (No.: ZK191090226).

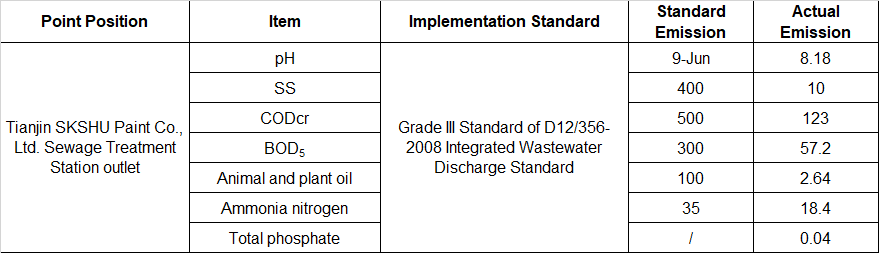

3. Type, Quantity and Destination of Pollutants Discharged by Tianjin SKSHU Paint Co., Ltd. (Tianjin Plant)

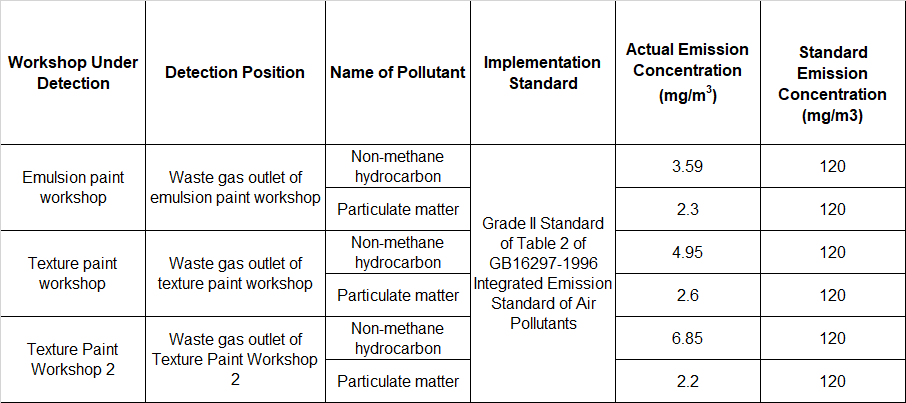

(1) The main pollutants of waste gas emissions include non-methane hydrocarbon and particulate matter.

Note: data source - the test report of Tianjin Sanfang Testing Center Co., Ltd. on November 27, 2019 (No.: Jin San Fang Jian (Wei) 1-201911-036).

(2) After treatment by the company's sewage treatment station, sewage is discharged into the municipal sewage pipe network and then into the Shuangqing Sewage Treatment Plant for centralized treatment.

Note: data source - the test report of Tianjin Sanfang Testing Center Co., Ltd. on November 27, 2019 (No.: Jin San Fang Jian (Wei) 1-201911-036).

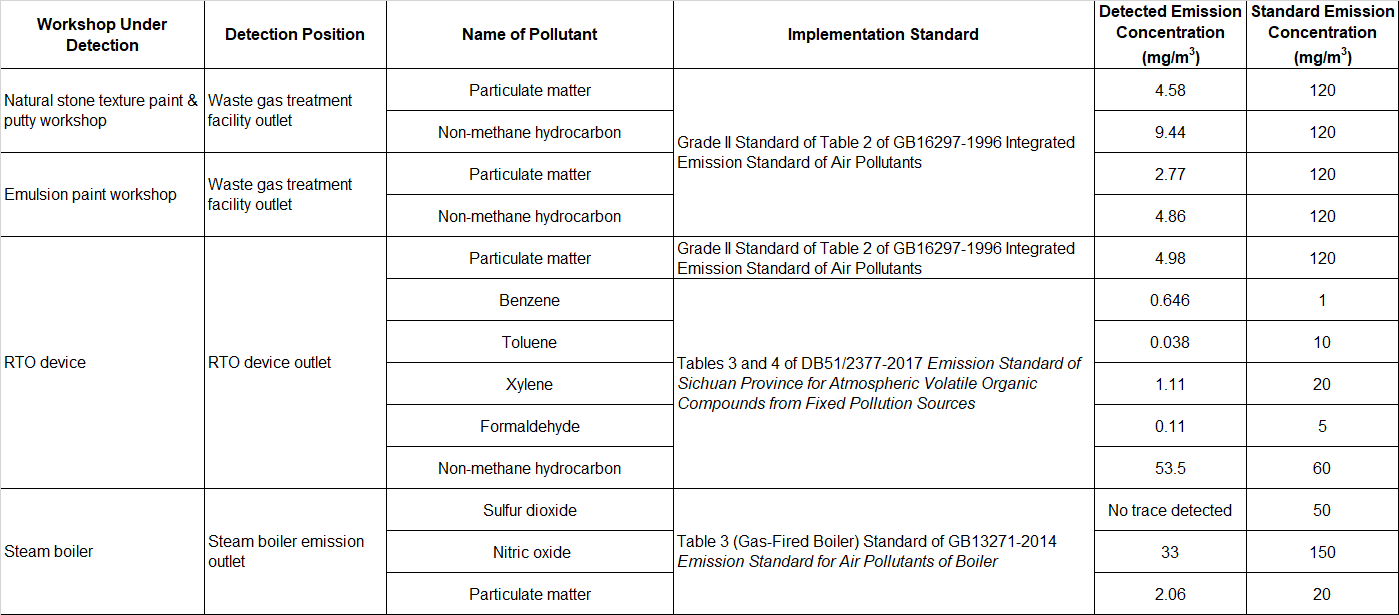

4. Types, Quantity and Destination Of Pollutants Discharged by Sichuan SKSHU Paint Co., Ltd. (Sichuan Plant)

(1) The main pollutants of exhaust gas emissions include non-methane hydrocarbon and particulate matter.

Note: data source - the test report of Sichuan Kaile Detection Technology Co., Ltd. on March 26, 2019 (No.: Kai Le Jian Zi (2019) No.03416W).

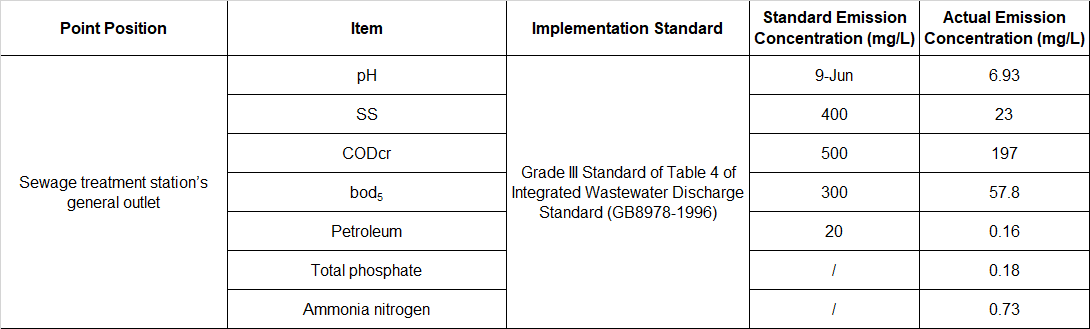

(2) After treatment by the company's sewage treatment station, sewage is discharged into Qionglai No.3 Sewage Treatment Plant for treatment through the municipal pipe network.

Note: data source - the test report of Sichuan Kaile Detection Technology Co., Ltd. on March 26, 2019 (No.: Kai Le Jian Zi (2019) No.03416W).

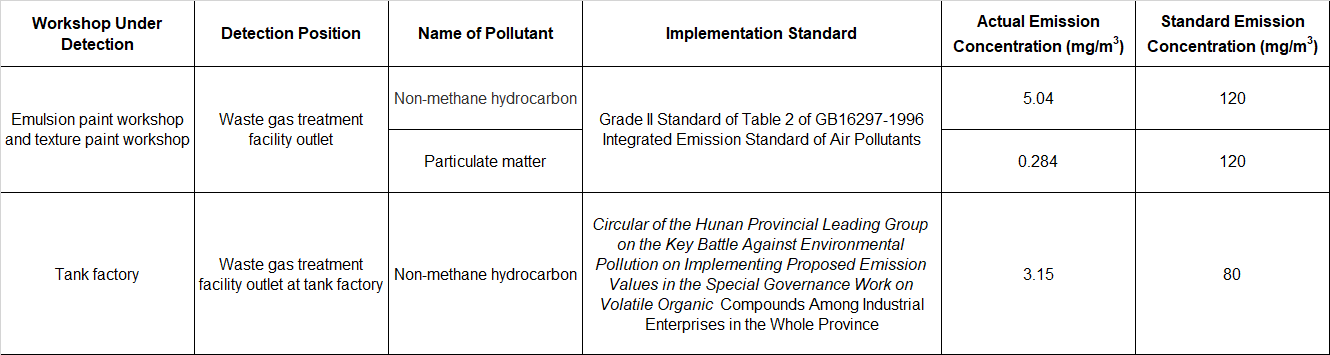

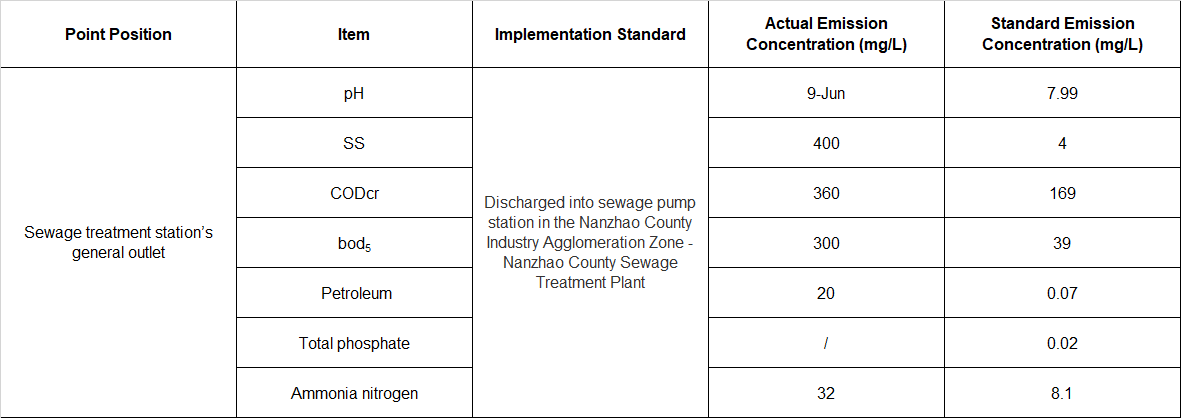

5. Type, Quantity and Destination of Pollutants Discharged by Henan SKSHU Paint Co., Ltd. (Henan Plant)

(1) The main pollutants of exhaust gas emissions include non-methane hydrocarbon and particulate matter.

Note: data source - the test report of Henan Micron Detection Technology Co., Ltd. on October 22, 2019 (No.: WMJC [2019] No. 0923-E04).

(2) After treatment by the company’s sewage treatment station, sewerage is discharged into the sewage pump station in the Nanzhao County Industry Agglomeration Zone and finally the Nanzhao County Sewage Treatment Plant after centralized treatment.

Note: data source - the test report of Henan Micron Detection Technology Co., Ltd. on October 22, 2019 (No.: WMJC [2019] No. 0923-E04).

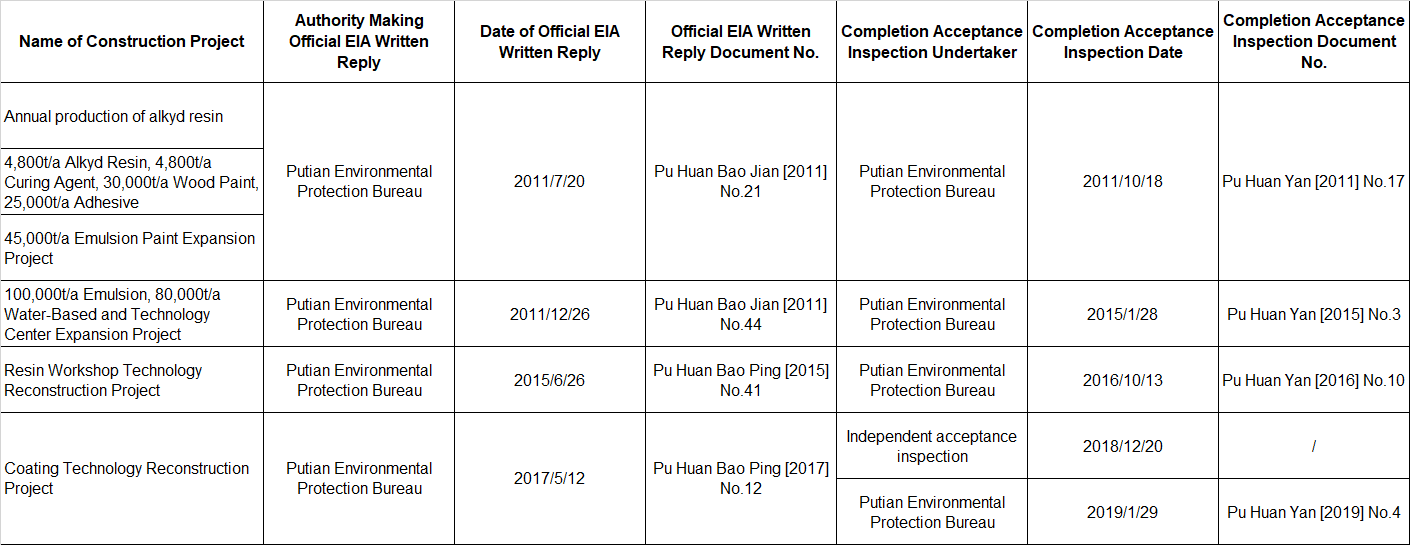

IV. Construction Project EIA and Other Administrative Permits for Environmental Protection

1. SKSHU Paint Co., Ltd.

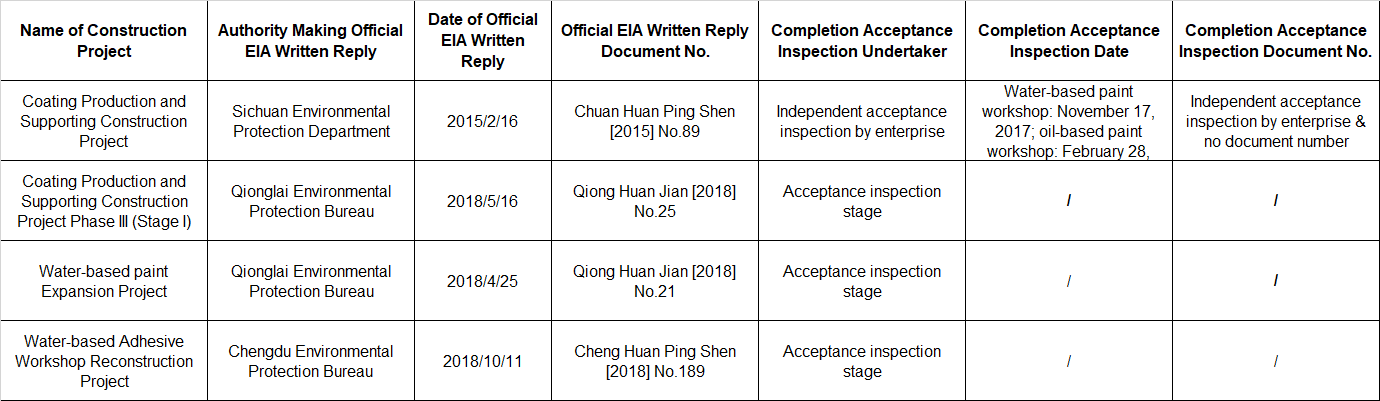

2. Sichuan SKSHU Paint Co., Ltd.

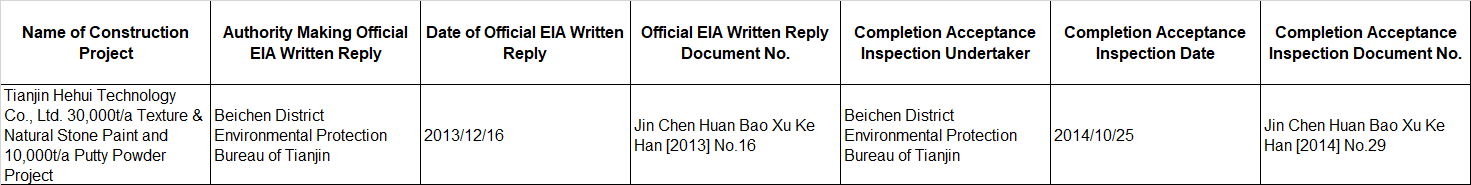

3. Tianjin SKSHU Paint Co., Ltd.

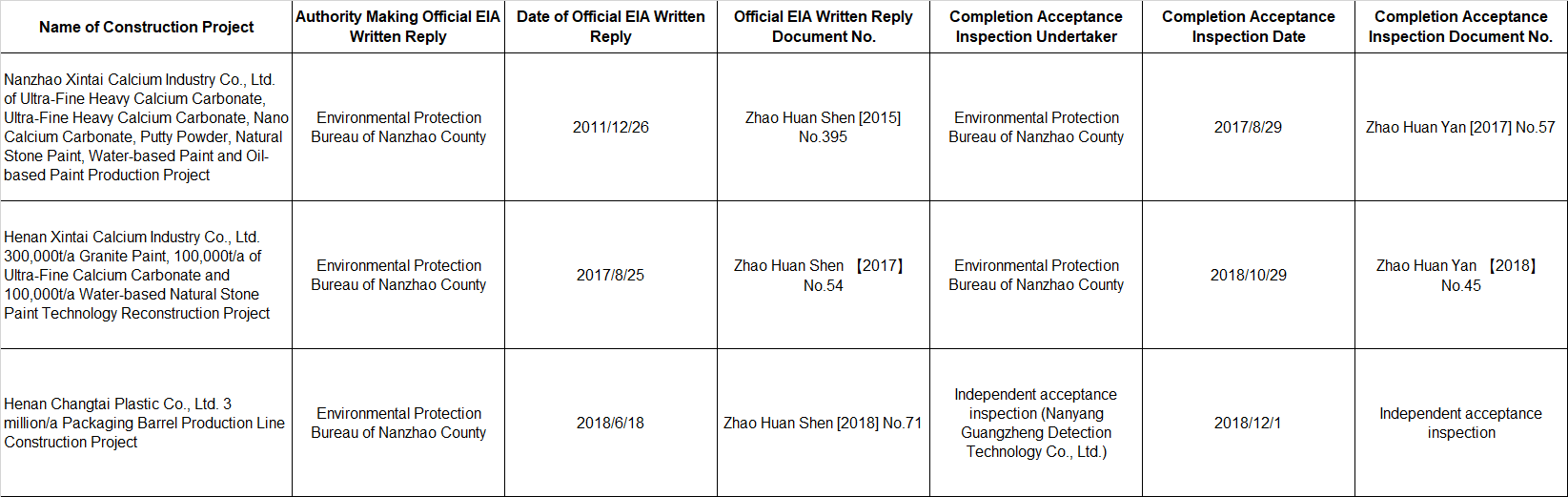

4. Henan SKSHU Paint Co., Ltd.

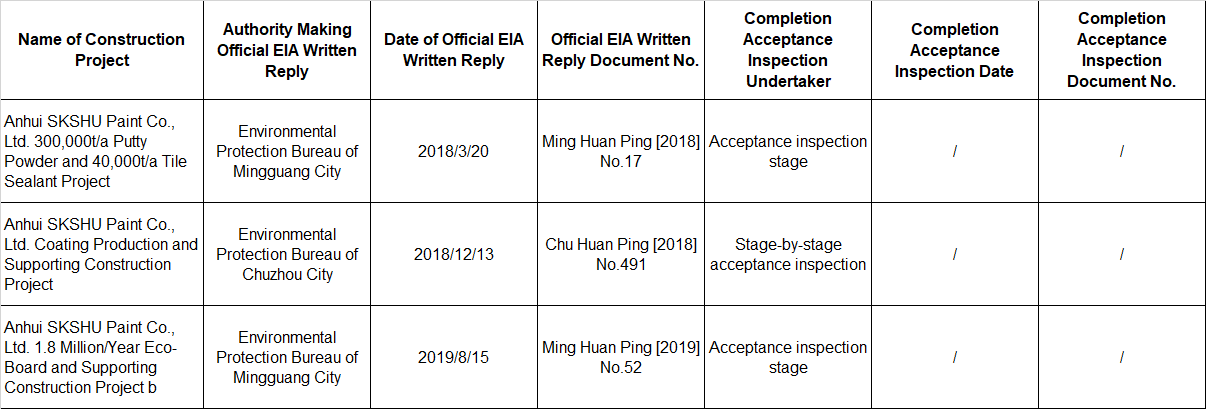

5. Anhui SKSHU Paint Co., Ltd.

V. Contingency plan for environmental emergencies

All factories of the 3TREES Group have compiled their Contingency Plans for Environmental Emergencies, which have been reviewed by experts and reported to local bureaus of ecology and environment for filing.

The contingency drills organized by various 3TREES plants in 2019 mainly include:

In June 2019, 3TREES (Putian Plant) held a contingency rescue drill on solvent dispersion kettle leakage in wood paint workshop.

In September 2019, 3TREES (Tianjin Plant) organized an emulsion barrel leakage accident drill.

In October 2019, 3TREES (Henan Plant) organized an emulsion barrel leakage contingency drill.

In May 2019, 3TREES (Henan Plant) organized a corrosive additive barrel breakage contingency drill.

In April 2019, 3TREES (Sichuan plant) organized a raw material leakage contingency drill.